Manufacturing Software Designed for You

DSD has helped manufacturers from all over the world choose the right software to reduce costs, improve production quality and more. A truly complete manufacturing software solution integrates with your ERP and prevents unnecessary downtime, while increasing manufacturing efficiency, quality and profit margins.

Acumatica Cloud ERP Manufacturing Edition

Acumatica Manufacturing works for make-to-stock, make-to-order, engineer-to-order, project centric, job shop, batch, and repetitive manufacturing processes.

Streamline production planning and shop floor with customer management, sales orders, inventory, purchasing, accounting, and financial reporting to provide real-time coordination of activities across your entire business.

Meet Your Schedules

The manufacturing ERP software allows customers to forecast demand while optimizing resources for effectiveness and cost control. All this is accomplished with a full-suite of modules available at any time.

Track Your Costs

Harness the ability to track labor costs and materials as you manage your projects. Also, compare standard and planned production costs to actual costs of production for more accurate metrics.

Grow Together

As you grow and change your business, have confidence that make-to-stock, make-to-order, engineer-to-order, project centric, job shop, batch, and repetitive manufacturing functions powerfully and completely.

One Single Solution

Acumatica Manufacturing Edition offers real-time coordination of your business activities from one central location, while cross-application integration enables you to have visibility across the entire organization wherever you are.

Acumatica Manufacturing Resources

SAGE INTACCT

Distribution and Manufacturing Operations for Sage Intacct

Start swiftly and efficiently managing your operational and financial workflows with Distribution and Manufacturing Operations for Sage Intacct. Cut through the clutter, embrace automation, and simplify your procedures to enhance productivity across various teams, from the manufacturing area to administrative operations, without complicating your system.

Scale growth

Harness the power of cloud native software that evolves with your business, supporting growth and adaptability.

Reduce cost of goods sold

Simplify and automate your operations, saving time and effort while optimising efficiency for maximum productivity.

Real-time insights on one platform

Spot opportunities and make decisions quicker, while providing valuable insights to your internal and external stakeholders.

Anytime, anywhere productivity

Stay connected on the go with secure access, enabling you to manage your operations anytime, anywhere.

Sage Intacct Resources

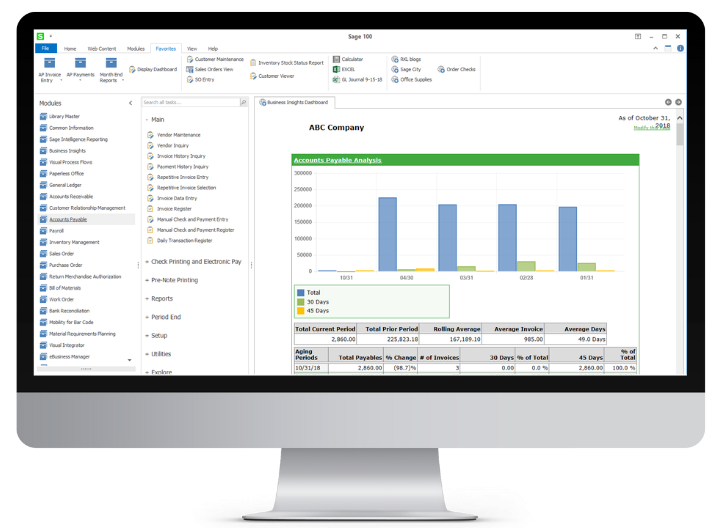

SAGE 100

Manufacturing Management Software

Three Sage 100 ERP powerful ERP manufacturing software modules, Bill of Materials, Work Order Processing, and Material Requirements Planning, provide detailed and accurate tracking and reporting throughout the entire manufacturing process-from forecasting to the shop floor, and on to completion.

Inventory Requirements Planning

With a clear perspective of existing inventory stock levels, open buy and sales orders, and manufacturing material requirements, evaluate existing supply and demand functions. The requirement for each inventory item is calculated using a combination of build times, lead times, and supply and demand calculations.

Custom Scripting

Create automations and workflows to auto-populate fields without having to click a single button, such as condition checks, basic alarms, and computations. Businesses may quickly import files from practically any third-party application into Sage 100 using Visual Integrator.

Custom Office

Save tens of thousands of dollars on modifications and upgrade to the needed software while preserving existing modifications. Fields may be easily added, edited, and reported on to satisfy the information collecting needs of individual businesses, and fields may be relabeled to match the terminology they use on a daily basis.

Production Management

With a centralized production process, businesses can track expenses, optimize inventories, and monitor production statuses, giving them complete visibility into assembly, manufacturing, or fabrication business’s production state and instant demand.